挑战

Develop a space-saving air delivery solution tailored for bid pump applications that operates independently of CO2.

供应链困境与成本上升

餐馆依赖饮料销售,而饮料的利润往往高于食品。然而,碳酸化和糖浆泵所需的二氧化碳 (CO2) 给我们的客户带来了巨大的挑战。二氧化碳成本增加、供应链中断,甚至二氧化碳罐被盗,都可能导致销售损失和客户不满。由于经营利润微薄,这些问题对于像密歇根州本顿港的 Sabroso 这样以社区为重点的小型企业来说尤其沉重。

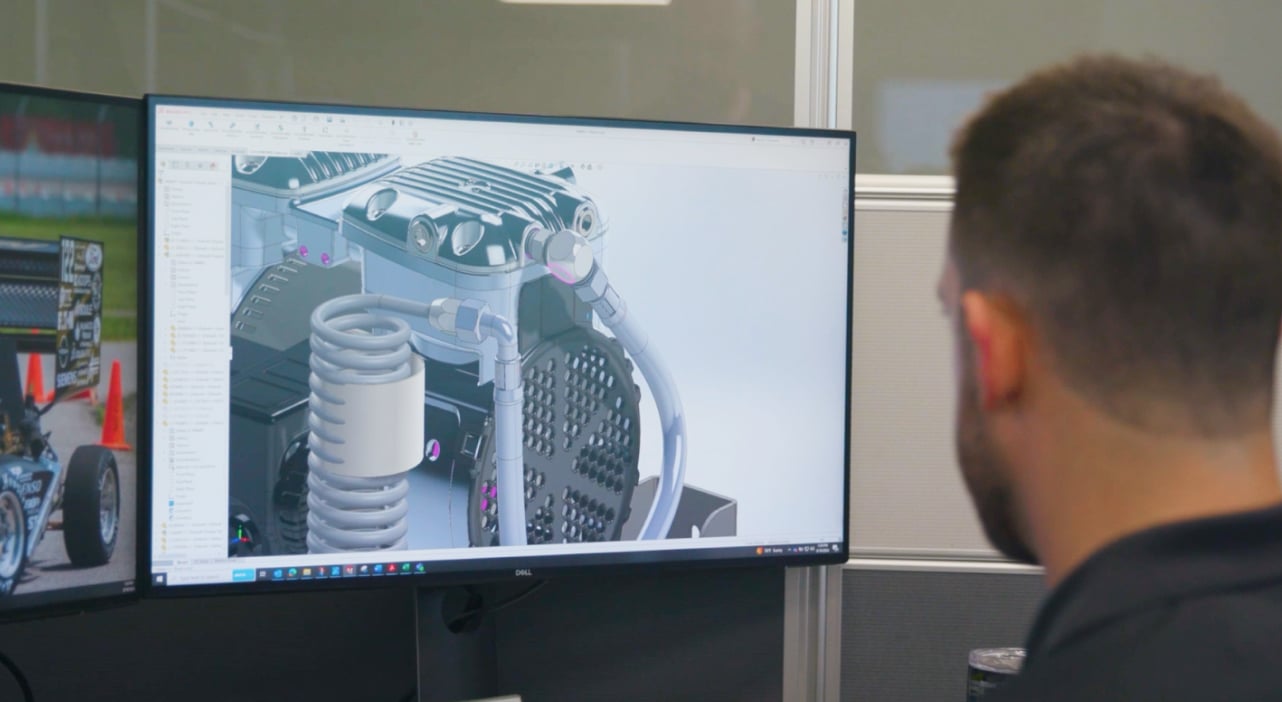

At Gast, also located in Benton Harbor, we recognized an opportunity to tackle these issues directly. Our team witnessed the CO2 supply chain challenges firsthand during a visit to this local restaurant. By focusing on non-essential CO2 usage, like in syrup pumps for beverage dispensers, our goal was to reduce costs, eliminate supply risks, and lower emissions without compromising operational efficiency.

解决方案

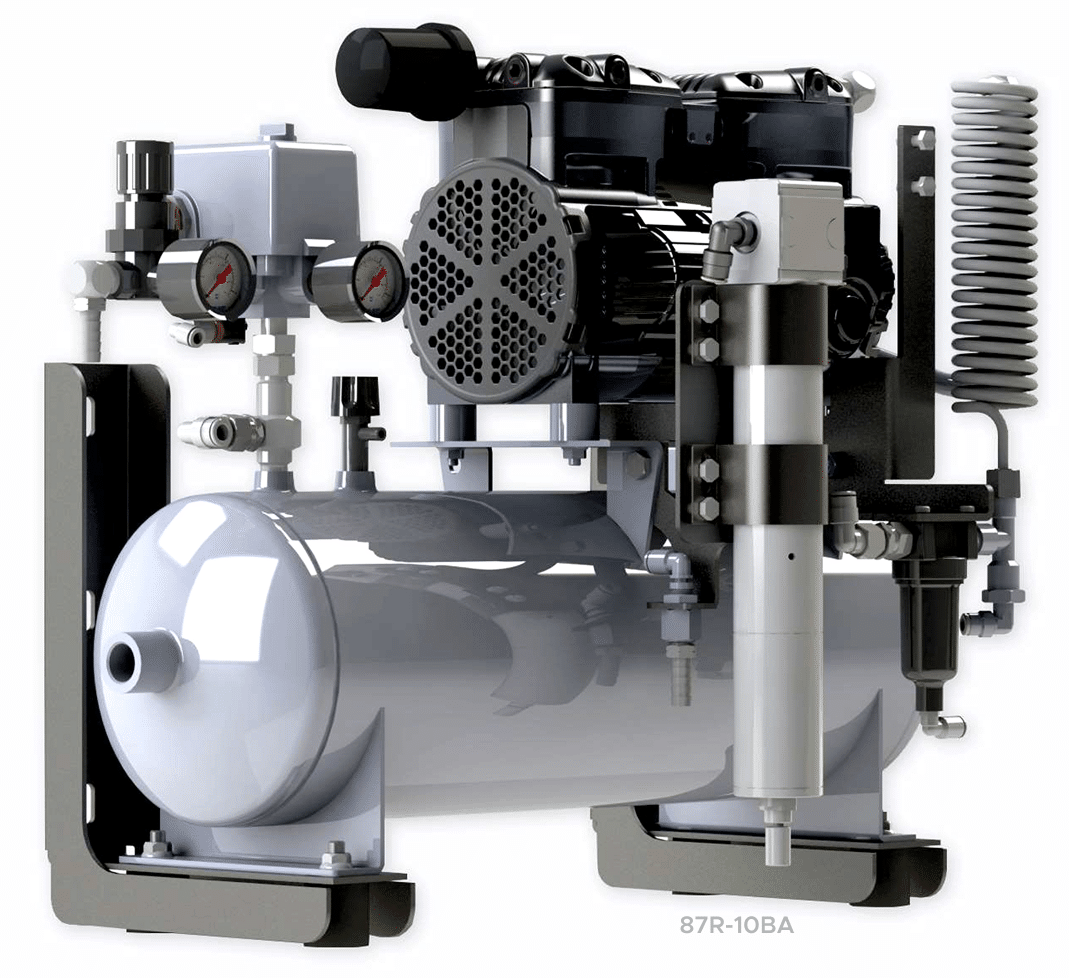

Gast developed the BEV G6 CO2 Reduction System, a compact, plug-and-play system that replaces CO2 with compressed dry air in non-essential beverage applications. The BEV G6 integrates seamlessly into existing CO2 delivery systems, connecting just in front of bag-in-box (BIB) syrup pumps to push syrup to dispensing machines using free, abundant air.

获取报告

简化饮料操作,降低二氧化碳成本,享受更安静、更可靠的性能。下载下面的完整规格表,了解 Gast 如何提高您的利润。

加斯特为饮料行业设计的系统是唯一一个带有空气干燥器的系统,可提供干燥、洁净的空气。

计算您的储蓄他们的成果

运营成本下降

减少二氧化碳排放量

Faster Installation Time

Compared to Traditional Systems

“Instead of using the CO2 we’re using air as an alternative. The CO2 that would have been used is now air, so we’ll be saving that much every time.”