The Challenge

Develop a space-saving air delivery solution tailored for bid pump applications that operates independently of CO2.

Supply Chain Struggles and Rising Costs

Restaurants depend on beverage sales, which often have higher margins than food. However, the carbon dioxide (CO2) necessary for carbonation and syrup pumps creates substantial challenges for our customers. Increasing CO2 costs, supply chain disruptions, and even theft of CO2 tanks can result in lost sales and unhappy customers. Due to their tight operating margins, these issues are especially burdensome for small, community-focused establishments like Sabroso in Benton Harbor, Michigan.

At Gast, also located in Benton Harbor, we recognized an opportunity to tackle these issues directly. Our team witnessed the CO2 supply chain challenges firsthand during a visit to this local restaurant. By focusing on non-essential CO2 usage, like in syrup pumps for beverage dispensers, our goal was to reduce costs, eliminate supply risks, and lower emissions without compromising operational efficiency.

The Solution

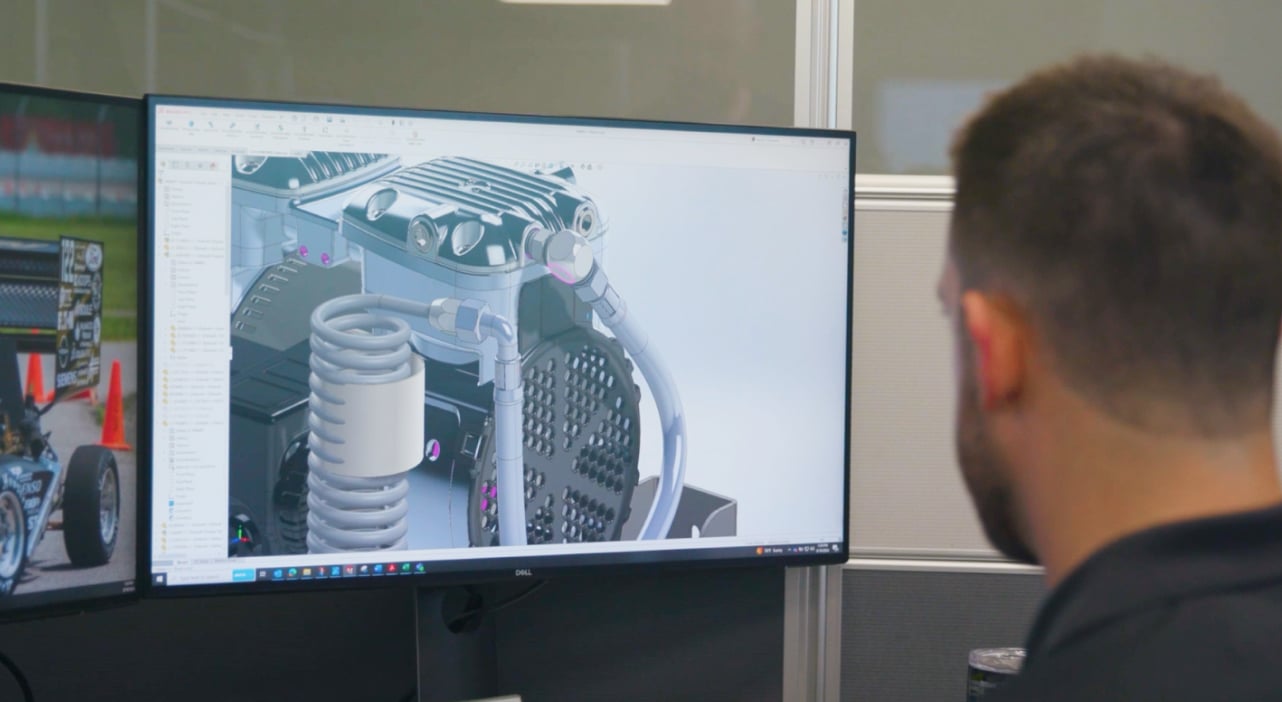

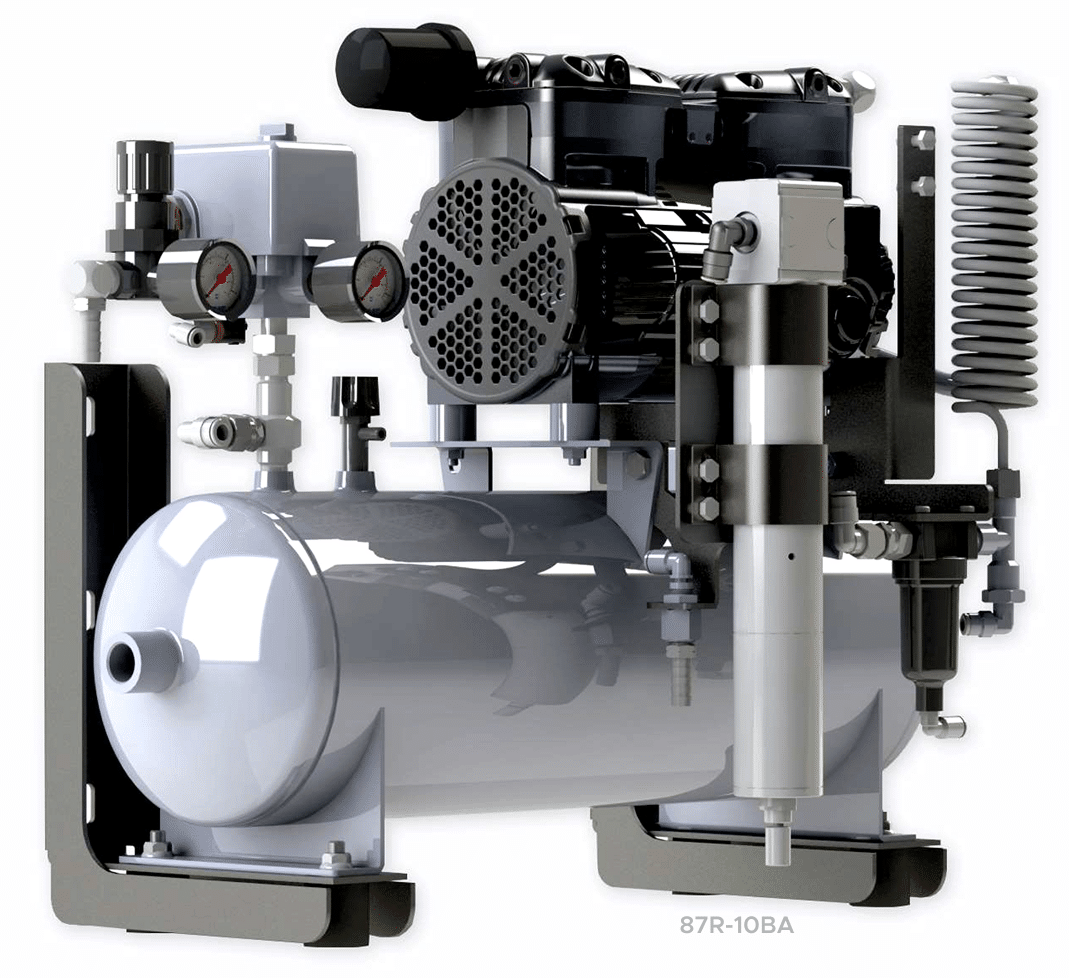

Gast developed the BEV G6 CO2 Reduction System, a compact, plug-and-play system that replaces CO2 with compressed dry air in non-essential beverage applications. The BEV G6 integrates seamlessly into existing CO2 delivery systems, connecting just in front of bag-in-box (BIB) syrup pumps to push syrup to dispensing machines using free, abundant air.

Get the Report

Streamline your beverage operations, reduce CO2 costs, and enjoy quieter, more reliable performance. Download the full spec sheet below to see how Gast can boost your bottom line.

Gast’s system for the beverage industry is the only one designed with an air dryer to push dry, clean air.

Calculate Your SavingsTheir Results

Operational Costs Fell

Reduction in CO2 Emissions

Faster Installation Time

Compared to Traditional Systems

“Instead of using the CO2 we’re using air as an alternative. The CO2 that would have been used is now air, so we’ll be saving that much every time.”