The Challenge

Minimize McDonald’s CO2 usage amid COVID-19 supply chain disruptions, while advancing long-term reductions in the restaurant’s future carbon footprint.

A Community Hub Meets Modern Demands

McDonald’s is a global icon of fast service and consistent quality, where beverages like Coca-Cola are a cornerstone of the customer experience. In Corinth, MS, a family-owned McDonald’s franchise owned by Jeff and Tyler Gamble thrives as a community hub for coffee crowds, kids, and busy families. Jeff, who worked at McDonald’s before becoming an owner, and his son Tyler, who is highly involved in McDonald’s sustainability efforts, have been part of the community for years—making their customers also their neighbors. This deep community connection makes operational efficiency even more critical, as the Gambles strive to serve their local patrons quickly and consistently.

However, quick-service restaurants face mounting challenges: high beverage demand, supply chain disruptions, and the need for efficiency to remain profitable. This case study highlights how Gast’s innovative beverage dispensing technology transformed operations at this franchise, providing a model for others.

The Solution

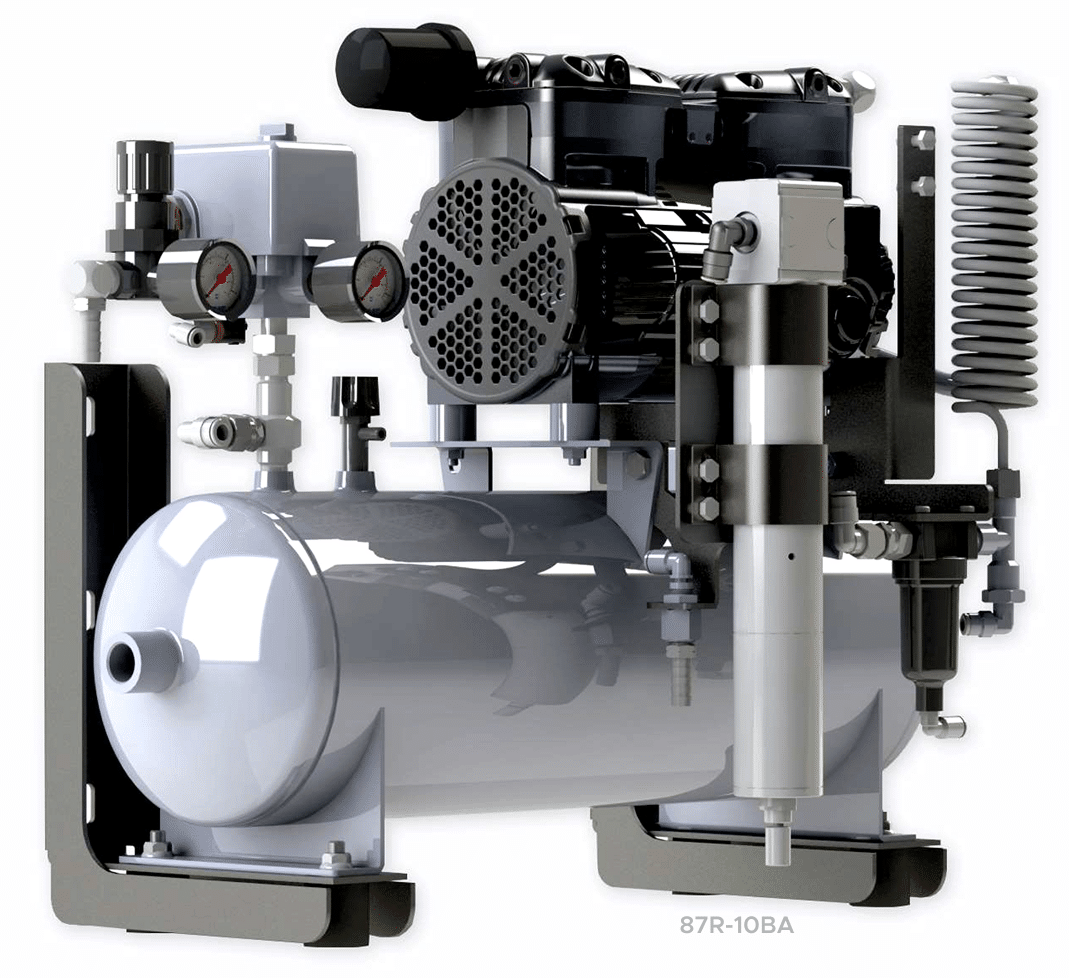

To tackle these issues, the Gambles partnered with Gast, whose engineering team absorbed the project and worked closely with the McDonald’s franchise to develop a tailored solution. Together, they implemented Gast’s BEV G6 CO2 Reduction System, a game-changer for quick-service restaurants. The Gast team’s collaborative approach ensured the system would meet the franchise’s specific operational needs while addressing broader industry challenges. The BEV G6 uses compressed air to power up to six Bag-in-Box pumps, slashing CO2 use by 50%. An integrated air dryer eliminates moisture, ensuring reliability, while automated dispensing delivers consistent drink quality. Working hand-in-hand with the McDonald’s team, Gast’s technicians achieved 50% faster installation (as quick as 60 minutes), allowing the system to integrate seamlessly into daily operations without disrupting service to the community.

Explore The SystemGast’s system for the beverage industry is the only one designed with an air dryer to push dry, clean air.

Calculate Your SavingsTheir Results

CO2 Costs Dropped

Operational Costs Fell

Reduction in CO2 Emissions

“Gast’s a no-brainer for any quick-service restaurant.”